Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer

Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer Semi Dull Yarn Manufacturer Polyester Yarn Factory

Semi Dull Yarn Manufacturer Polyester Yarn Factory Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply

Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply Good Resilience 0.32mm TPU+TPEE Monofilament Yarn

Good Resilience 0.32mm TPU+TPEE Monofilament Yarn Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use

Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use- All new products

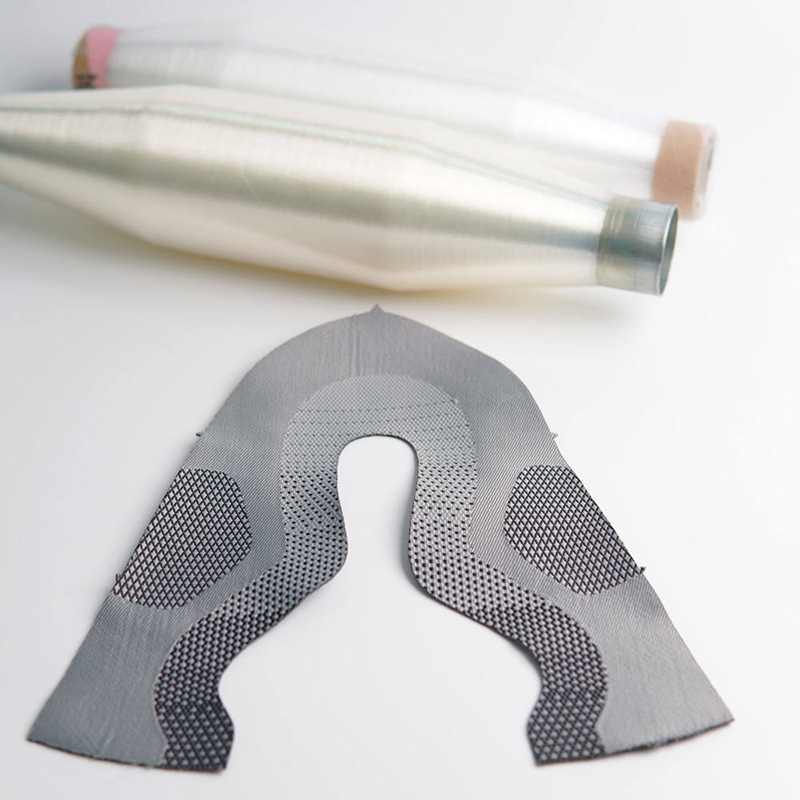

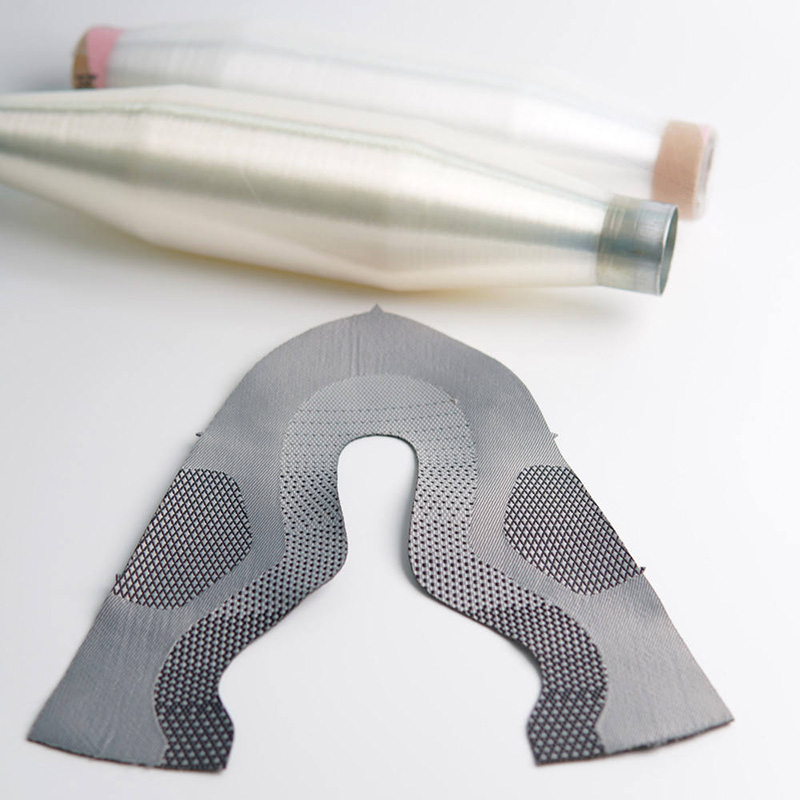

Wholesale 0.32mm TPU+TPEE Monofilament Yarn

Send Inquiry

As a professional monofilament yarn manufacturer, Sinrylion's 0.32mm TPU+TPEE composite monofilament yarn redefines industry standards with its excellent performance. This product combines the high elasticity and wear resistance of TPU with the high temperature resistance (-50°C to +150°C) and anti-aging properties of TPEE to create ultra-high strength (tensile strength ≥50MPa) and chemical corrosion resistance, perfectly adapted to harsh industrial environments. Its 0.26mm precision diameter design ensures that the product achieves ultra-thin wall thickness and structural stability in scenarios such as medical device catheters, sports equipment reinforcement layers, and industrial filters. It also supports customized color, hardness, and conductive modification to meet the needs of diversified industries.

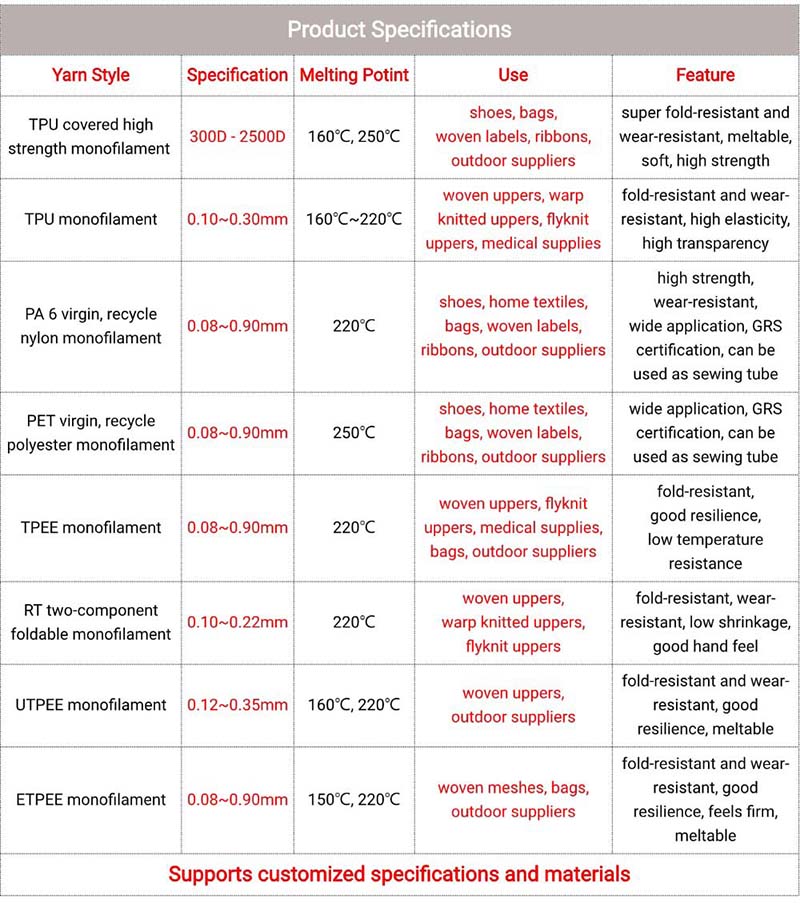

Product Description

Material: TPU+TPEE

Spec: 0.12mm - 0.35mm

Melting Point: 150℃/220℃

Sample: Free

Feature: Fold-resistant and wear-resistant, Good resilience, Meltable

Use: Woven uppers, Outdoor suppliers

Certificate: GRS Certificate, OEKO-TEX Standard 100, ISO9001, SGS

Product advantages

Excellent material properties

- High elasticity & fatigue resistance: TPU gives the monofilament excellent resilience, TPEE enhances bending fatigue resistance, and repeated stretching does not deform.

- Weather resistance & chemical corrosion resistance: Adapt to extreme temperatures from -40℃ to 120℃, resist UV, oil stains and most solvents, and extend service life.

- Precision diameter control: 0.26mm±0.01mm ultra-fine specifications, smooth surface without burrs, ensuring processing consistency and end product quality.

Diversified application scenarios

- Sports equipment: tennis racket strings, fishing lines, climbing ropes and other high-strength scenarios;

- Medical field: surgical sutures, wearable rehabilitation equipment support materials;

- Industrial textiles: industrial screens, conveyor belt reinforcement layers, safety protection fabrics;

- Consumer electronics: headphone cable reinforcement cores, smart wearable device flexible structural parts.

Environmental protection and safety

- Comply with RoHS and REACH standards, no heavy metal additions, pass biocompatibility tests, and meet medical and consumer product safety requirements.

Sinrylion factory strength

Sinrylion has been deeply engaged in the research and development of monofilament materials for 35 years, providing full-specification TPU/TPEE/PA monofilament yarns from 0.05mm to 3.0mm, covering more than 20 industries such as medical, textile, automotive, and aerospace. The factory is equipped with German precision extrusion production lines and ISO 13485 medical-grade clean workshops, supporting OEM/ODM deep customization: from raw material ratio optimization, profiled wire cross-section design to functional coating treatment (antibacterial/UV-resistant/flame-retardant), ensuring that customers obtain differentiated competitive products. With a database of 3000+ successful cases, we can develop high-resilience support wires for sports protective gear brands, or customize oil-resistant sealing monofilaments for automobile manufacturers, helping you quickly seize market opportunities.

Sinrylion relies on its own raw material modification laboratory and full-process quality control system (, to achieve precise control of TPU+TPEE monofilament yarn performance. The production capacity advantage is significant: 10 automated production lines ensure a monthly production capacity of more than 200 tons, supporting 48-hour delivery of emergency orders. We continue to provide one-stop services from technical consultation to proofing to mass production for global industrial customers.

Consult now → Get free samples and customized solutions

Whether you need standard specifications of monofilaments or customized development of special performance, Sinrylion can provide you with reliable support with three commitments of high cost performance, rapid response, and technical escort. Click to contact an engineer to unlock the innovative application potential of monofilament materials!

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский