Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer

Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer Semi Dull Yarn Manufacturer Polyester Yarn Factory

Semi Dull Yarn Manufacturer Polyester Yarn Factory Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply

Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply Good Resilience 0.32mm TPU+TPEE Monofilament Yarn

Good Resilience 0.32mm TPU+TPEE Monofilament Yarn Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use

Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use- All new products

Wholesale Fancy yarn Centipede Yarn Manufacturer spec 16NM 26NM 18NM 24NM OEM

Send Inquiry

Wholesale cindy fancy yarn in China, has focused on fancy Yarn manufacturing since 1983. Support OEM spec 16NM 26NM 100%Nylon, 18NM 24NM 100%Polyester. Sinrylion is a professional centipede yarn manufacturer.

Product Specification

Crystal Mink Yarn

1/16NM 0.4CM 100%N

1/10NM 0.9CM 100%N

100%Nylon

Strong,

High Tenacity

Knitting,

Knitting Sweater,

Glove And Scarf

Plastic Bags,

Outer Carton,

Pallet

OEKO-tex Standard 100

ISO 9001

GRS Certificate

5000 Kilogram/

Kilograms per Day

Brand Name:

Sinrylion

Type:

Fancy Yarn

Product name:

Feature:

Usage:

Packing:

Quality:

AAA or AA Grade

Place of Origin:

Fujian, China

Sample:

For free

MOQ:

1 KG

Certificate:

Capacity:

Crochet Knit Fancy Yarn

Specification

Count

Composition

Imitate Mink Hair Yarn

1.3CM/13Nm

100%Nylon

Imitate Mink Hair Yarn

2.0Cm/7Nm

100%Nylon

Nylon Feather Yarn

From 7Nm~16Nm

-

Polyester Feather Yarn

From 3Nm~8Nm

-

Lantern Yarn

3.7Nm/7Nm

-

Toothbrush Yarn

4.2Nm/10Nm

-

Ladder Yarn Bright

5Nm

-

Ladder Yarn

5.2Nm

40%Nylon/60%Acrylic

Tape Yarn

From 3Nm~8Nm

40%Nylon/60%Acrylic

Metallic Yarn

M.MH.MD.MX type

100%Polyester

Provide Knit Service as Customer Samples Needed

FACTORY VIDEO

PRODUCT VIDEO

Related Product

|

Sinrylion Main Fancy Yarn |

||

|

Yarn Style |

Specification |

Material |

|

Mink Yarn |

1/16NM 0.85CM |

100%Nylon |

|

1/13.5NM 1.3CM |

||

|

1/7NM 2CM |

||

|

1/6.5NM 4CM |

||

|

1/5.6NM 5CM |

||

|

1/4.8NM 8CM |

||

|

Crystal Mink Yarn |

1/16NM 0.4CM |

100%Nylon |

|

1/10NM 0.9CM |

||

|

Curly Mink Yarn |

1/10NM 0.9CM |

100%Nylon |

|

Coral Velvet |

1/6NM |

100%Polyester |

|

1/9NM |

||

|

1/13NM |

||

|

Provide Service As Customer Needed: Specification |

||

Production Process

Raw material preparation

The production of fancy yarn begins with the preparation of raw materials. Usually, fancy yarns use natural fibers such as cotton, linen, wool, etc., or synthetic fibers such as polyester, nylon, etc. These raw materials undergo cleaning, drying, opening, carding, drawing and other processes to make yarn that can be used for weaving.

Weaving

Weaving is the core part of fancy yarn production. At this stage, the yarn is woven into gray cloth through a loom. Looms are usually divided into flat looms and circular looms. Plain looms are mainly used to produce plain fabrics, while circular looms are used to produce threaded fabrics. During the weaving process, the quality and appearance of the gray fabric can be controlled by adjusting the parameters of the loom, such as warp and weft density, yarn tension, etc.

Dyeing

Dyeing is another important step in fancy yarn production. During the dyeing process, the gray cloth is immersed in the dyeing liquid. After a certain time and temperature, the dye and the yarn react chemically, thereby giving the yarn a specific color and texture. Common dyeing methods include loose fiber dyeing, yarn dyeing and garment dyeing.

Tidy

The dyed gray fabric needs to be finished to give it the desired fancy effect. Finishing includes cutting, embroidery, printing and other techniques. Cutting is the use of a shearing machine or manual cutting of the surface of the embryonic fabric to form various patterns; embroidery is the use of an embroidery machine to embroider embroidery threads on the embryonic fabric to form exquisite patterns; printing is the use of a printing machine to embroider colored dyes Printed on the embryonic fabric to form various patterns.

Finished product inspection and packaging

Finally, the finished fancy yarn needs to be inspected and packaged. The purpose of finished product inspection is to ensure that the quality and color of each batch of products meet the requirements. Packaging is the process of sorting, folding, and boxing the inspected products to facilitate transportation and sales.

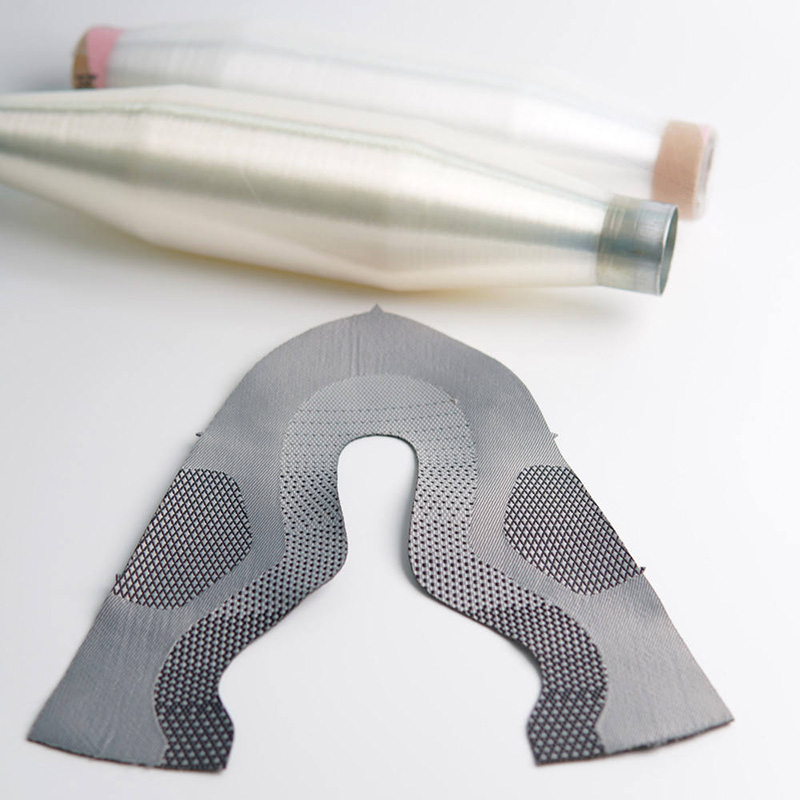

Characteristics of centipede yarn

Structural features

The structure of centipede yarn is made up of multiple thin yarns intertwined with each other in a certain pattern. Each thin yarn is precisely calculated and arranged to form a structure similar to the feet of a centipede. This structure gives centipede yarn a high density and strength, and also gives it a unique texture and texture.

Appearance features

The appearance of centipede yarn has unique texture and pattern, and its shape and pattern can be designed and adjusted according to different needs. Normally, the surface of centipede yarn presents a texture similar to that of centipede feet. This texture has a strong three-dimensional and layered feel, making its appearance more unique and attractive.

Performance characteristics

High strength: Due to the structural characteristics of centipede yarn, it has high strength and wear resistance, and can maintain good condition after multiple washings and uses.

Soft and comfortable: The yarn of centipede yarn is thin and soft, and its structure also makes it feel comfortable, giving people a warm and soft feeling.

Good breathability: The structure of centipede yarn makes it have good breathability and hygroscopicity, which can effectively eliminate moisture and odor, keeping the body dry and comfortable.

Good durability: Due to the advantages of centipede yarn such as high strength, softness and comfort, and good breathability, it has a long service life and can withstand the test of time.

Application areas

Centipede yarn has a wide range of applications, mainly used in clothing, home textiles, decoration and other fields. In the field of clothing, centipede yarn can be used to make various clothing accessories, collars, cuffs, etc.; in the field of home textiles, centipede yarn can be used to make bed sheets, quilt covers, pillowcases, etc.; in the field of decoration, centipede yarn can be used to make Various decorations, wall hangings, etc.

About Fancy yarn

Fancy yarn refers to the yarn with special structure and appearance effect obtained by using special raw materials, special equipment or special technology to process the fiber or yarn in the process of spinning and thread making. It is a decorative yarn product.

Fancy yarn is a yarn with various appearance characteristics obtained by the principle of overfeeding, such as Centipede Yarn Mink Yarn, Chenille Yarn, Loop yarn, Knitting tape yarn, Belly yarn, Tam tam yarn, TT yarn, Feather yarn, Sanding yarn etc.The fabric woven by this kind of yarn feels fluffy, soft, has good warmth retention, and has a unique appearance and strong three-dimensional effect. It can be used as clothing fabrics and decorative materials. It can be used for both light summer clothing and heavyweight. Winter clothing.

Our Advantages

1. We are a yarn manufacturer with more than 40 years experience.

2. We have more than 400 sets of different machines. Like POY spinning equipment, texturing machine, drawing machine, twisting machine, warping machine and so on. Among them, we have about two hundred twisters.

3. We can produce twenty tons of yarn per day.

4. Our products passed the ISO9001quality system and Oeko-tex Standard 100 ecological textile certification.

5. We produce high quality yarns.

About Sinrylion

Jinjiang Xinglilai Group Co Ltd was founded in March 1983. The group's total registered capital is 50 million RMB. The headquarters is located in wuli industrial area in Jinjiang. After 40years of development ,it has branch companies as follow, Jinjiang Xinglilai Yarns Co Ltd, Dongguan Xinglilai Warp&weft Yarns Co Ltd,Quanzhou Xinxingliali Fibre&testile Co Ltd and Changsheng Fibre Industy Trading Co Ltd in vietnam.Our partners have throughout Fujian,Guangdong,zhejiang area, hongkong,europe, southeast asia and other regions. Established a good reputation and won wide praise from customers. At the same time, the company relies on huge production development and large scale, combined with advanced technology and equipment, which established the foundation on the spinning market.Our Products passed the ISO9001 quality system and Oeko-tex Standard 100 ecological textile certification,provide various specification stability color yarn.

Sinrylion Exhibition Certificates and Partners

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский