Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer

Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer Semi Dull Yarn Manufacturer Polyester Yarn Factory

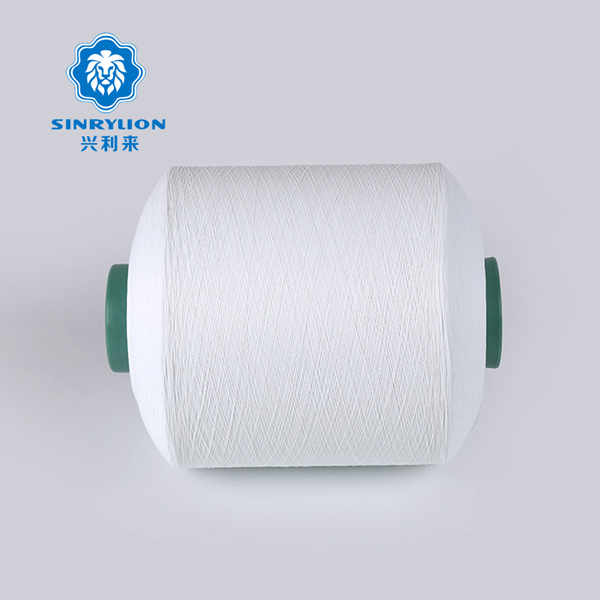

Semi Dull Yarn Manufacturer Polyester Yarn Factory Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply

Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply Good Resilience 0.32mm TPU+TPEE Monofilament Yarn

Good Resilience 0.32mm TPU+TPEE Monofilament Yarn Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use

Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use- All new products

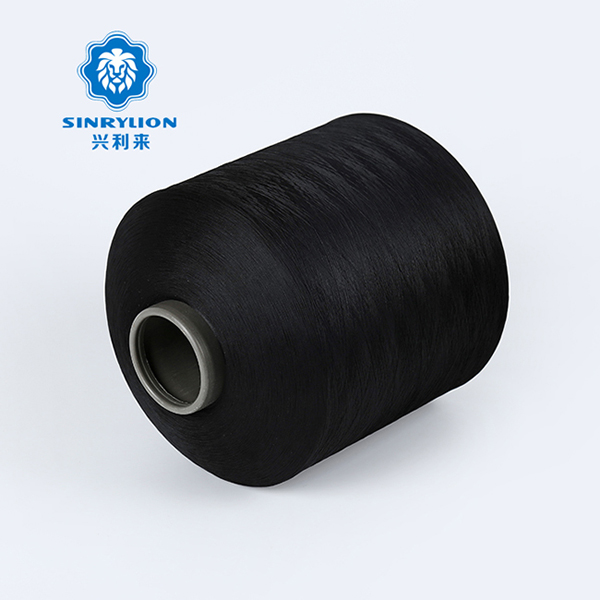

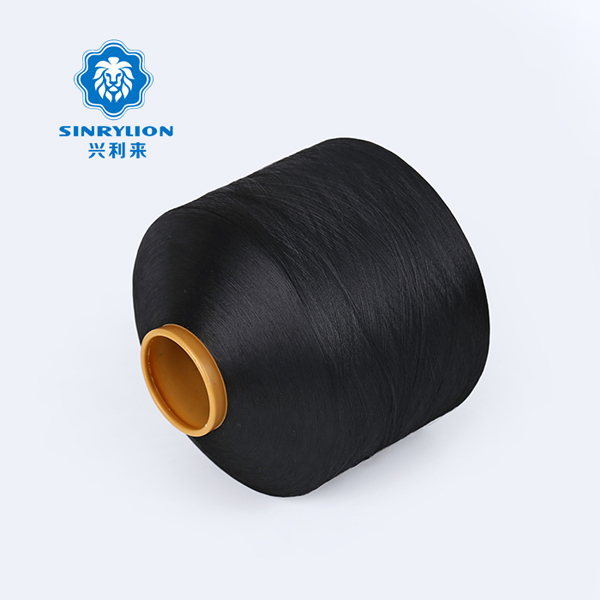

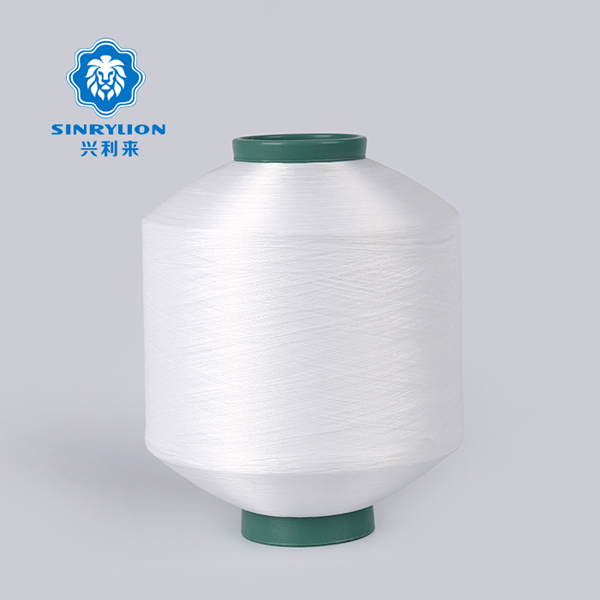

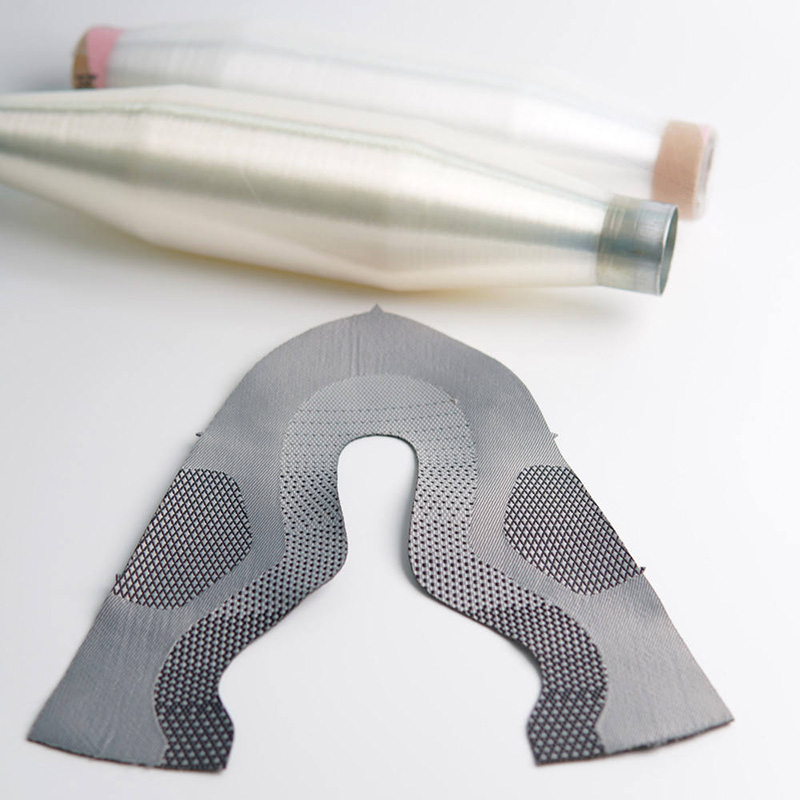

Rpet polyester recycled yarn

The production process of environmentally friendly polyester rpet yarn uses polyester chips from recycled plastic bottles, melt spinning to form filaments yarn, which are then wound into bobbin yarns using a twisting machine. The denier is 50D to 2000D FDY and DTY yarn.

Model:75D White FDY polyester recycled yarn

Send Inquiry

GRS Filament 75D Raw White FDY polyester recycled rpet yarn

1. Raw materials:

Selection: The raw materials of environmentally friendly polyester recycled yarn mainly include

polyester chips (PET) and recycled polyester chips. Environmentally friendly, low-pollution, and easily

degradable raw materials are selected to reduce environmental pollution during the production process,

reflecting the concept of environmental protection.

Processing: The polyester chips are strictly screened and cleaned to remove impurities and pollutants.

Recycled polyester rpet yarn needs to be sorted, cleaned, crushed, etc. to ensure its quality and purity.

The process is relatively complicated

2. Spinning

The processed polyester chips are heated and melted by a melting device to form a polyester melt.

The melt is then transported to the spinning box through a booster pump, a melt cooler, a melt pipe,

and other equipment. After being accurately measured by a metering pump, it enters the spinning assembly.

The spinneret in the spinning assembly extrude the melt stream to form filaments. The filaments are

cooled and solidified to form solid fibers. The oiled fibers are wound into silk cakes or tows by a winding machine.

3. Environmental protection measures

During the entire production process, strictly control the discharge of wastewater, waste gas and

waste residue to ensure compliance with national environmental protection standards.

Use environmentally friendly additives and dyes to reduce pollution to the environment.

Recycle and treat waste generated during the production process to achieve resource recycling.

4. Quality inspection:

Strict quality inspection of the environmentally friendly polyester yarn produced, including appearance,

strength, elongation, color fastness and other indicators.

Ensure that the product meets relevant standards and customer requirements.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский