Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer

Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer Semi Dull Yarn Manufacturer Polyester Yarn Factory

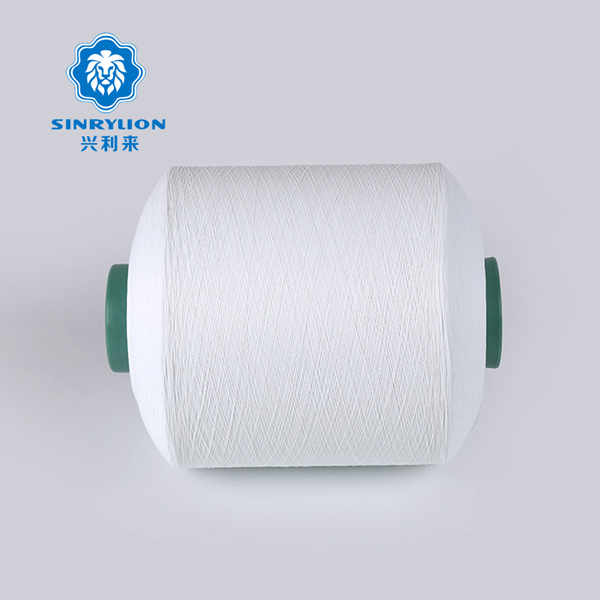

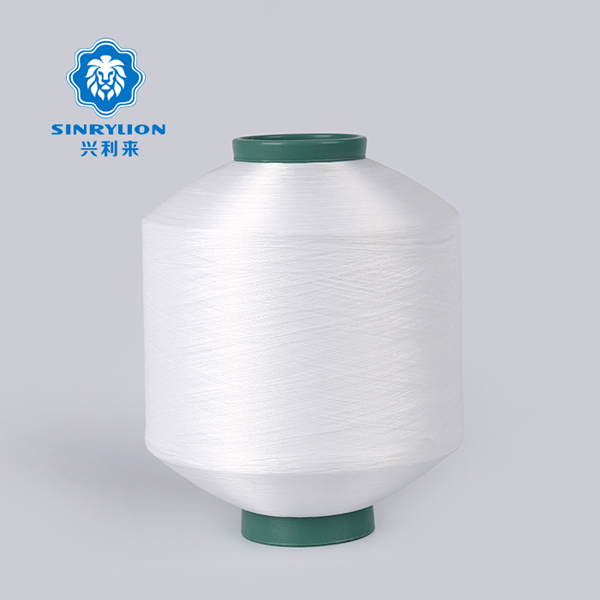

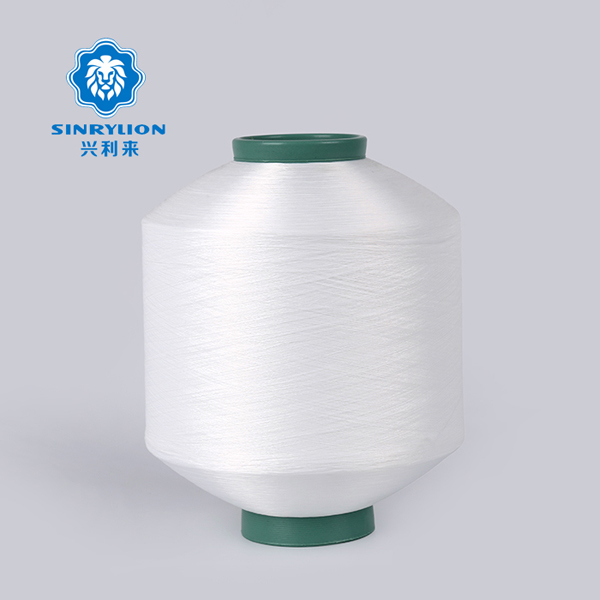

Semi Dull Yarn Manufacturer Polyester Yarn Factory Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply

Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply Good Resilience 0.32mm TPU+TPEE Monofilament Yarn

Good Resilience 0.32mm TPU+TPEE Monofilament Yarn Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use

Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use- All new products

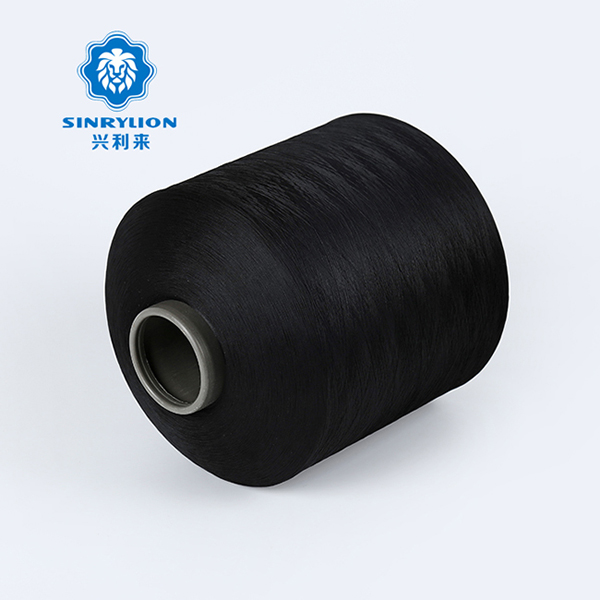

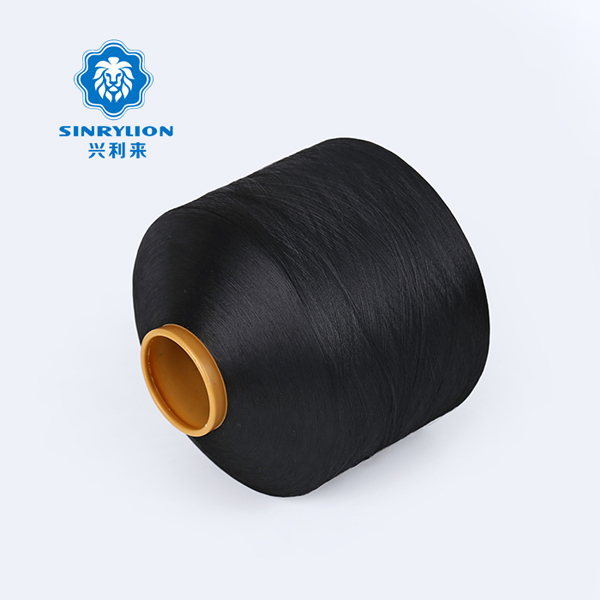

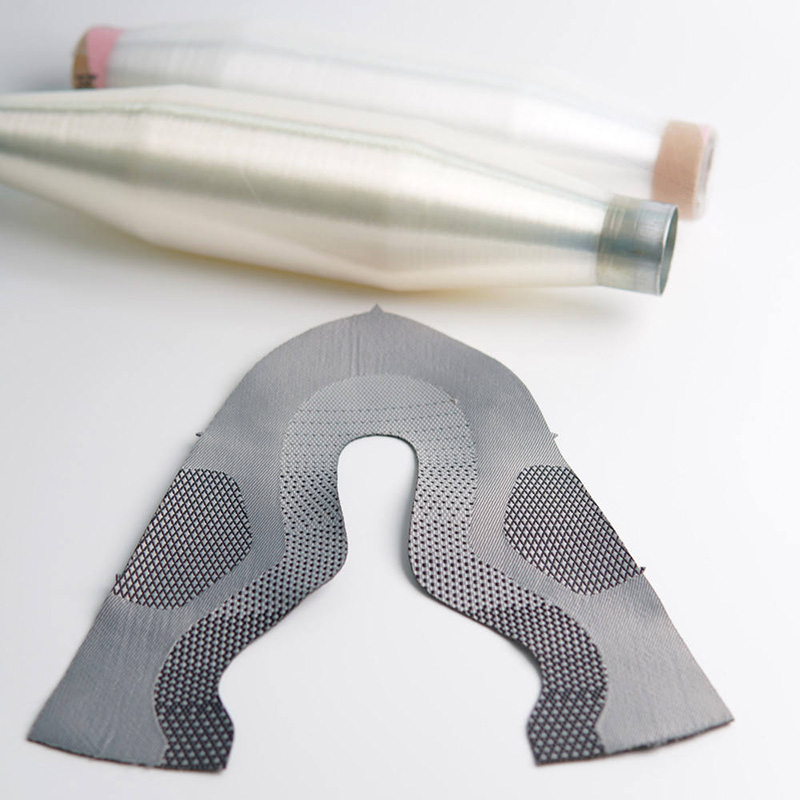

Polyester DTY Recycled Yarn Weft Textured Filament Yarn

Send Inquiry

Sinrylion polyester dty yarn manufacturer. Polyester DTY is obtained when Polyester POY is simultaneously twisted and drawn. DTY yarn is mainly used as a part of weaving and knitting of fabrics for making garments, home decorations, seat covers, bags and numerous different things. DTY yarn can be in Semi Dull or Bright or Triloble Bright depending upon the kind of areas of filaments.DTY is suitable for fabric end uses like outer/inner garments, skin-clinging garments, furnishings, upholstery, etc. This is a replacement of cotton and cotton blend yarns with very low moisture content.

Sinrylion is a leading of DTY Recycled Yarn manufacturer. A unique and wide range of DTY yarn is produced in our premises with the help of latest state-of-art machinery equipped with high-speed draw texturing technology which adjusts the levels of twisting and drawing in accordance to our customers specific requirements. Our manufacturing abilities encompass curating DTY yarn in varied lusters ranging from Semi Dull to Dope Dyed Black designed & customized as demanded by our weavers and other manufacturers. The production process is precisely supervised by expert technicians in order to ensure consistency in manufacturing superior quality yarn spools at every step of our intensive manufacturing process.

FACTORY VIDEO

PRODUCT VIDEO

Promote green manufacturing

The Xinhua News Agency reporter learned from the China Chemical Fiber Industry Association that China will vigorously develop recycled fiber, polylactic acid fiber, and degradable fiber to enhance the independent innovation capability and green manufacturing level of the chemical fiber industry and improve the recycling system.

Chemical fiber is one of the most important materials for industrial production and social life. The green manufacturing level of the chemical fiber industry reflects the ability of a country to produce cleanerly. At present, the world chemical fiber industry is accelerating its transition to a more environmentally friendly and green direction. China is the world's largest producer and consumer of chemical fiber. The huge market demand and production scale call for cleaner and environmentally friendly manufacturing methods.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский