What Is Good Resilience TPEE Monofilament Yarn?

2025-04-08

Table of Contents |

|

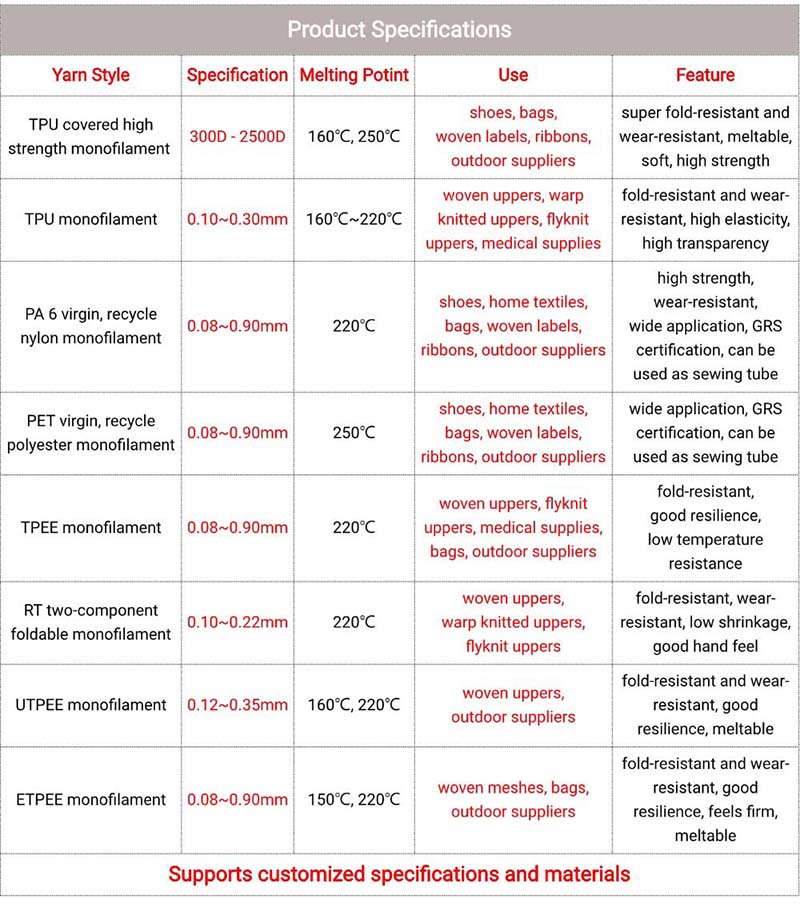

In the textile and industrial fields, choosing the right yarn plays a vital role in product quality. As an emerging high-performance material, TPEE monofilament yarn is gradually attracting the attention of many manufacturers and designers. TPEE is the abbreviation of Thermoplastic Polyester Elastomer. This material has excellent elasticity, wear resistance and temperature resistance, so it is widely used in many fields such as clothing, automobiles, electronics and packaging.

TPEE monofilament yarn manufacturing process: How to produce high-quality yarn?

The production of high-quality TPEE monofilament yarn requires strict control of three key links: raw materials, processing technology and post-processing. First of all, the selected raw materials can ensure that the yarn has good physical properties such as strength, ductility and temperature resistance at the initial stage. In the production process, melt spinning technology is widely used. This process can evenly melt the raw materials at high temperature, stretch them into fibers through fine molds, and then form delicate monofilament yarns.

Manufacturing process focus:

- Temperature control: Develop a fine temperature curve to ensure that the material is not thermally damaged during melting and solidification.

- Stretch ratio: Strictly control the stretch ratio to increase the crystallinity of the fiber, thereby enhancing the mechanical properties of the yarn.

- Cooling system: An efficient cooling system not only shortens production time, but also helps the stability of the yarn.

Reasonable process regulation can increase the breaking strength of the product by 10%~20%, which is of great significance for high-end manufacturing. By continuously introducing automated testing equipment and advanced online monitoring systems, professional manufacturers such as Sinrylion ensure that each batch of TPEE monofilament yarn meets high standards.

What is the difference between monofilament and nylon thread? What are the advantages of TPEE monofilament?

In the market, there are many types of monofilament yarns, and how to choose the most suitable material has become a key issue for manufacturers. Common monofilament materials such as nylon thread, polyester yarn and TPEE monofilament have certain differences in physical properties and application areas.

Comparison of main differences and advantages:

Elasticity and flexibility:

- TPEE monofilament yarn has better elasticity and can quickly return to its original shape after being stretched, which is suitable for applications that require frequent bending and stretching.

- Nylon thread is durable, but slightly lacks in elasticity.

Wear resistance and temperature resistance:

- TPEE monofilament yarn is not only wear-resistant, but also maintains stable performance under high temperature conditions, which makes it particularly suitable for automotive and electronic equipment fields.

- Nylon thread has relatively weak temperature resistance, and long-term high-temperature operation may cause performance degradation.

Processing and post-maintenance:

- The production process of TPEE monofilament yarn is precisely controlled, and the finished product has high consistency and stability.

- Although nylon yarn is mature, it may experience "broken wire" in some high-demand scenarios, and the tension control during the production process is more sensitive.

For this reason, more and more experts and engineers recommend the use of TPEE monofilament yarn in occasions with higher material performance requirements. Through comparative data and long-term feedback, TPEE monofilament yarn has gradually become the preferred material for industrial manufacturing and professional applications.

What is TPEE monofilament best used for? Application tips and suggestions

TPEE monofilament yarn is widely used in many fields due to its excellent physical and chemical properties. Next, we will share some practical application cases and suggestions to help you better understand and apply this high-performance yarn.

Main application areas:

- Automotive industry:

- In automotive manufacturing, TPEE monofilament yarn is often used in components such as interiors, seats and seat belts. Its high elasticity and wear resistance ensure stability after long-term use while reducing maintenance costs.

- Electronic equipment:

- Electronic product housings, internal connection structures and insulation materials will also use TPEE monofilament yarn to ensure that the product can maintain functional consistency even in high temperatures and complex environments.

- Clothing and sports equipment:

- Sportswear and high-end sports equipment have high requirements for material elasticity and comfort. Fabrics made of TPEE monofilament yarn not only have outstanding texture, but also have excellent tensile resistance, providing greater freedom and comfort for sports enthusiasts.

Application tips and suggestions:

- Choose the right production equipment:

- It is recommended to use an automated spinning system, which can accurately control temperature, speed and stretch ratio to ensure the uniformity and stability of the yarn.

- Regularly maintain equipment and test finished products:

- During the production process, it is recommended to check the machine regularly to ensure that the temperature sensor and stretching system are working properly. At the same time, the produced yarn is periodically tested for physical properties, such as breaking strength and elongation, to avoid product quality problems caused by equipment failure.

- Cooperate with professional manufacturers:

- In terms of material selection and production technology, cooperation with professional manufacturers with rich experience (such as Sinrylion) can help develop the best production strategy and improve the quality of finished products with the help of their advanced technology and data support.

Some reliable data in the industry show that correct equipment maintenance and process control can increase production efficiency by about 15%, while reducing product rework rate, further consolidating the competitive advantage of the production line.

Can monofilament yarn be used as sewing thread? Common questions and practical tips

In daily production, many technicians will ask: Is TPEE monofilament yarn suitable for use as sewing thread? The answer is yes - but some practical issues need to be paid attention to. According to different uses and requirements, reasonable application and debugging methods can make TPEE monofilament yarn play an excellent role in sewing, fixing and decoration.

Common problems and solutions:

Frequent wire breakage:

Some users find that the yarn is easy to break during use. In response to this problem, it is recommended to check the following points:

- Equipment tension setting: Ensure that the tension of the sewing equipment is moderate, avoid being too tight or too loose.

- Yarn storage: TPEE monofilament yarn should be stored in a dry, light-proof environment to prevent environmental factors from affecting quality.

- Preheating before use: In some high-demand applications, proper preheating can help improve the ductility and overall performance of the yarn.

Sewing adaptation issues:

For garments of different styles and materials, the use of TPEE monofilament yarn may require different types of sewing needles and equipment parameters. It is recommended to conduct small batch tests before changing materials to find the most suitable sewing configuration.

Environmental adaptability issues:

Although TPEE monofilament yarn has high temperature resistance, microstructural changes may occur in low temperature or humid environments. At this time, it is recommended to:

- Adjust sewing parameters, such as reducing sewing speed or increasing heating assistance;

- Select blended materials suitable for the environment to complement TPEE to ensure the final product effect.

Practical tips:

- Use professional tools: such as electronic tensiometers and temperature monitoring equipment, which can help to timely detect and solve problems in the production process.

- Regularly train employees: Ensure that operators are familiar with the characteristics and correct use of TPEE monofilament yarn.

- Keep in touch with manufacturers: Professional monofilament yarn manufacturer like Sinrylion usually provide technical support and on-site guidance, which is very helpful to overcome difficulties in actual operation.

The above practical suggestions for common problems not only help users improve product quality, but also bring highly operational solutions to daily production, ensuring that problems can be solved quickly and effectively when they arise.

How to select and maintain TPEE monofilament yarn?

In summary, TPEE monofilament yarn has demonstrated unique advantages in multiple industrial and consumer fields with its excellent elasticity, wear resistance and temperature resistance. Through precise production processes and strict quality inspections, it not only performs well in the manufacturing process, but also shows long-term stable performance in actual product applications.

When actually selecting and using, companies and professional technicians should pay attention to the following key points:

- Quality and data support: Choose manufacturers with advanced manufacturing equipment and reliable data support to ensure that each batch of yarn meets high standards.

- Equipment maintenance and testing: Regularly maintain production equipment and conduct physical property tests on finished products to ensure consistency during use.

- Personnel training and technical communication: Timely update knowledge and technology to ensure that operators can quickly respond to various problems in production.

- Continuous innovation: With the continuous changes in market demand, TPEE monofilament yarn will continue to integrate new technologies and new materials in the future, bringing a wider range of application prospects.

In the future, with the further popularization of automation and intelligent manufacturing, the production efficiency and quality of TPEE monofilament yarn will be further improved. Industry experts predict that in the next few years, its application in new energy vehicles, smart wearables and high-tech electronic products will be further expanded, which also puts forward higher technical and management requirements for enterprises. Through continuous innovation and improvement, TPEE monofilament yarn is bound to become an important force in promoting technological progress in related industries.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский