Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer

Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer Semi Dull Yarn Manufacturer Polyester Yarn Factory

Semi Dull Yarn Manufacturer Polyester Yarn Factory Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply

Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply Good Resilience 0.32mm TPU+TPEE Monofilament Yarn

Good Resilience 0.32mm TPU+TPEE Monofilament Yarn Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use

Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use- All new products

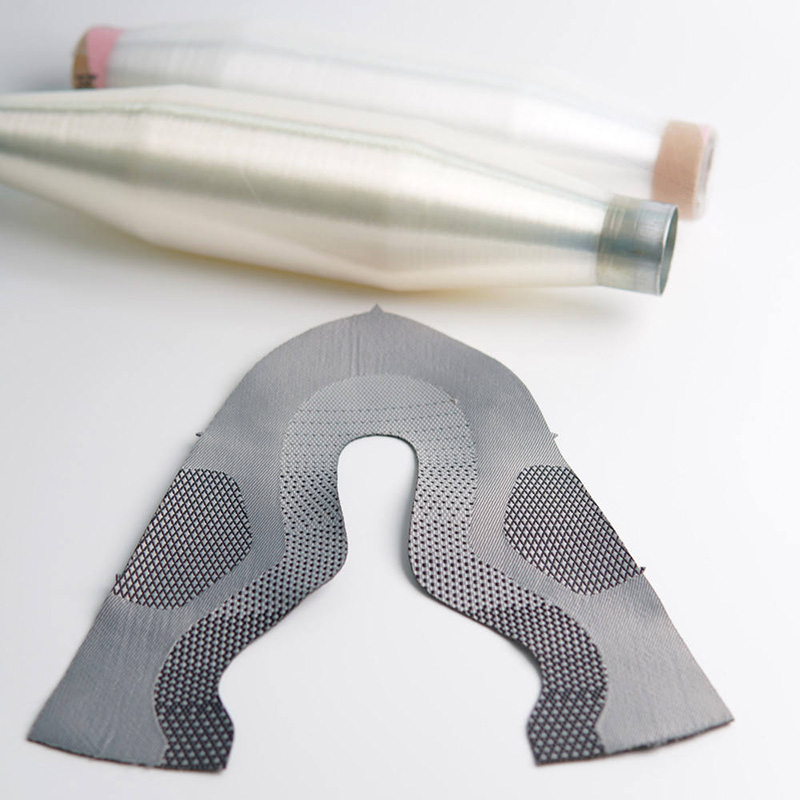

Buy 75D/36F 120TPM Weaving Polyester Yarn Suppliers

Send Inquiry

Buy 75D/36F 120TPM Weaving Polyester Yarn Suppliers

polyester weaving yarn suppliers

Our 75D DTY Filament Polyester Yarn Factory In China, our factory does its best in a series of process

from raw material preparation to final packaging.

Polyester DTY (polyester drawn yarn) is a common polyester product, widely used in textile, clothing,

home textile and other fields. 75D polyester DTY means that the linear density of polyester yarn is 75

decitex (dtex is the unit of linear density, 1 decitex is equal to 10,000 meters of polyester yarn weight

1 gram).

polyester yarns factory in china

The following is the production process of 75D polyester DTY:

1. Preparation of raw materials: The main raw material is polyethylene terephthalate (PET) chips, which

are usually made from petrochemical products. At the same time, some auxiliary raw materials are also

required, such as catalysts, stabilizers, etc.

2. Drying of chips: In order to ensure the smooth progress of the production process, the chips need to

be dried to remove moisture from the chips.

Melt extrusion: The dried chips are placed in the extruder, heated at high temperature to melt them, and

then the molten PET chips are extruded into continuous filaments under the action of the extruder.

4. Stretching: The extruded filament is stretched to reduce its linear density. Stretching can be performed

on a single-stage stretching machine or a multi-stage stretching machine. According to different stretching

multiples, polyester yarns with different linear densities can be obtained.

5. Winding and forming: The stretched polyester yarn needs to be wound and formed for subsequent

processing and use. During the winding and forming process, the polyester yarn can be subjected to a certain

heat setting treatment to improve its stability.

6. Post-processing: In order to improve the performance of polyester yarn, some post-processing can be

performed, such as dyeing, printing, coating, etc.

7.Inspection and packaging: The completed polyester DTY is inspected to ensure that its quality meets the

standards. Qualified products are packaged and prepared for shipment.

The above is the production process of 75D polyester DTY. In the actual production process, it is also necessary

to adjust and optimize according to specific needs and equipment conditions.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский