Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer

Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer Semi Dull Yarn Manufacturer Polyester Yarn Factory

Semi Dull Yarn Manufacturer Polyester Yarn Factory Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply

Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply Good Resilience 0.32mm TPU+TPEE Monofilament Yarn

Good Resilience 0.32mm TPU+TPEE Monofilament Yarn Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use

Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use- All new products

Twisted Color Dope Dyed Polyester Filament Yarn

Send Inquiry

Twisted Color Dope Dyed Polyester Filament Yarn

Quality:

1. Glossiness: High-quality polyester original spray-dyed yarn should have uniform and bright glossiness.

2. Color: The color should be bright and full, without color difference or color flower phenomenon.

3. Cleanliness: The surface of the yarn should be clean, free of impurities, oil or spots.

4. Tensile elasticity: Polyester original spray-dyed yarn should have moderate elasticity when stretched,

and the length after stretching should not show obvious deformation or retraction.

5. Strength: According to the standard of polyester natural yarn, the breaking strength of single yarn

should meet certain standards

6. Abrasion resistance: Polyester original spray-dyed yarn should have good abrasion resistance to ensure

that it is not easy to wear or break during subsequent processing and use.

7. Washing color fastness: After multiple washings, the color of the yarn should remain unchanged or change very little.

8. Friction color fastness: In the friction test, the color of the yarn should not fall off or stain on other objects easily.

9. Perspiration color fastness: In an environment simulating human sweating, the color of the yarn should remain stable.

10. Hand feel: Polyester original spray-dyed yarn should have a soft, smooth and delicate hand feel,

and feel heavy in the hand, with a certain sense of drape.

11. Source of raw materials: High-quality polyester original spray-dyed yarn is usually made of high-quality polyester raw materials.

12. Production process: Advanced production technology can ensure the quality and stable performance of the yarn.

Color card:

Rich colors and environmental protection: Twisted FDY polyester yarn can be used in a variety of colors

to meet the needs of different woven labels. At the same time, polyester, as an environmentally

friendly material, can be recycled and reused, which is in line with the modern green environmental

protection concept.

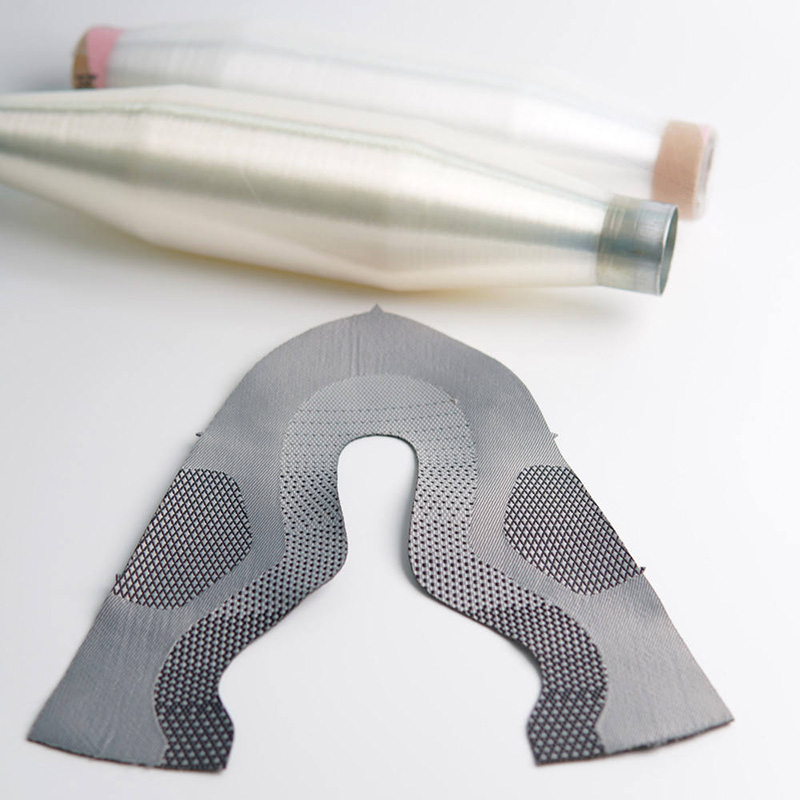

Application:

Production flow chart:

The twisting process of our factory is to twist and entangle two or more single yarns according to a

certain pattern to form certain kinks and entanglements between the yarns. For FDY polyester yarn,

the twisting process not only improves the strength and wear resistance of the yarn, but also increases

the softness and feel of the yarn, making the woven label more comfortable when it touches the skin.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский